Ready for every truing situation

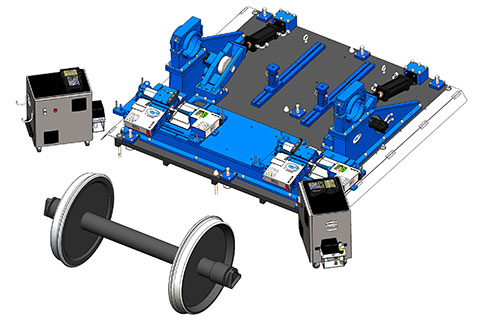

Delta Wheel focuses on one thing. Excellent Wheel Truing Systems. From fully customizable static systems to our industry leading portable Wheel Hog, Delta equipment is built to keep our great American rail system and the people who run it work more efficiently and effectively. We build American ingenuity and precision into every product.

We specialize in building the very best wheel truing systems in the world and support them with personalized on-site training and 24/7 customer service.

- Made to order. Built to last.

- Fully customizable for every installation.

- The most innovative truing solution in the world.

- One-of-a-kind portability and precision.

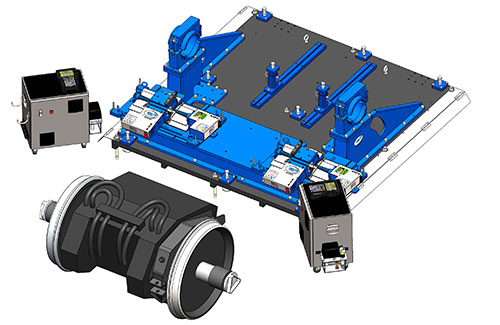

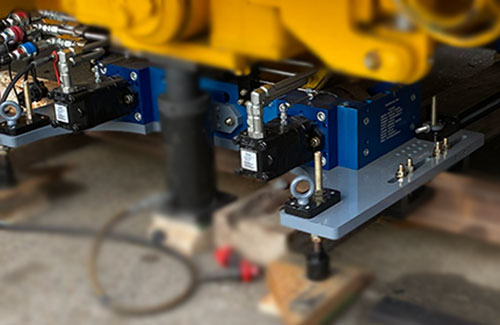

additional Accessories to maximize the usage of your portable cnc wheel lathe

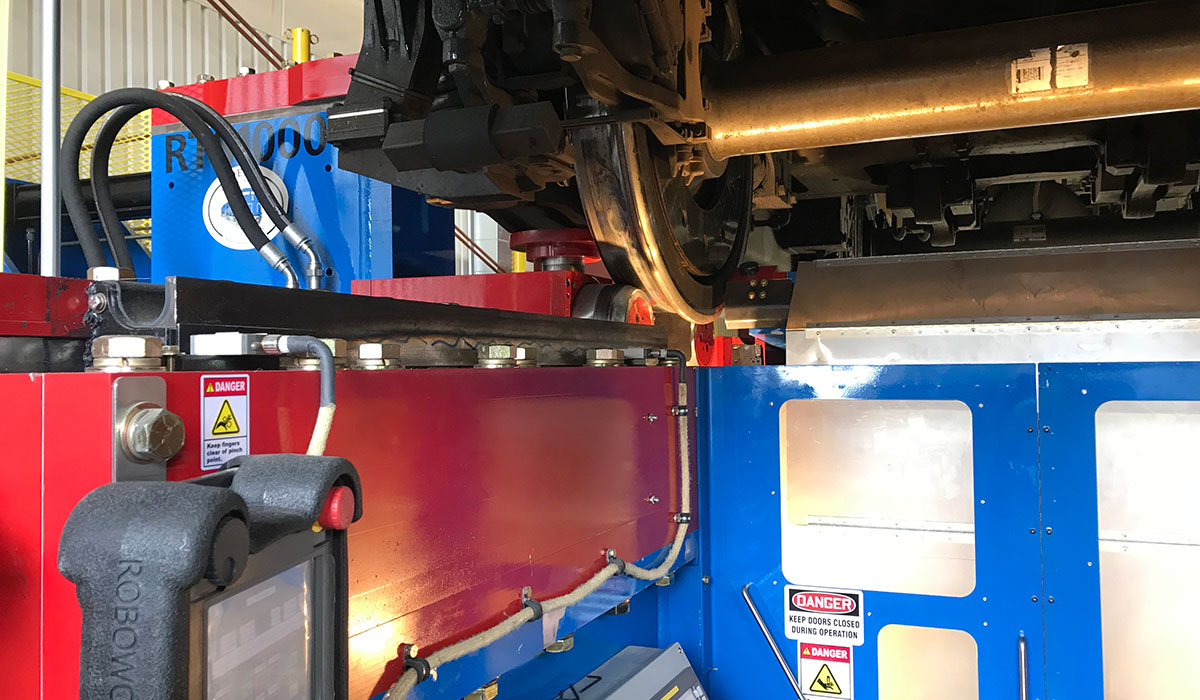

PAD 1000 Port-a-Drive

The PAD1000 portable friction hydraulic drive is paired with the Wheel Hog giving you the ability to re-profile non-powered wheel sets while they are still on the vehicle/bogie/wagon.

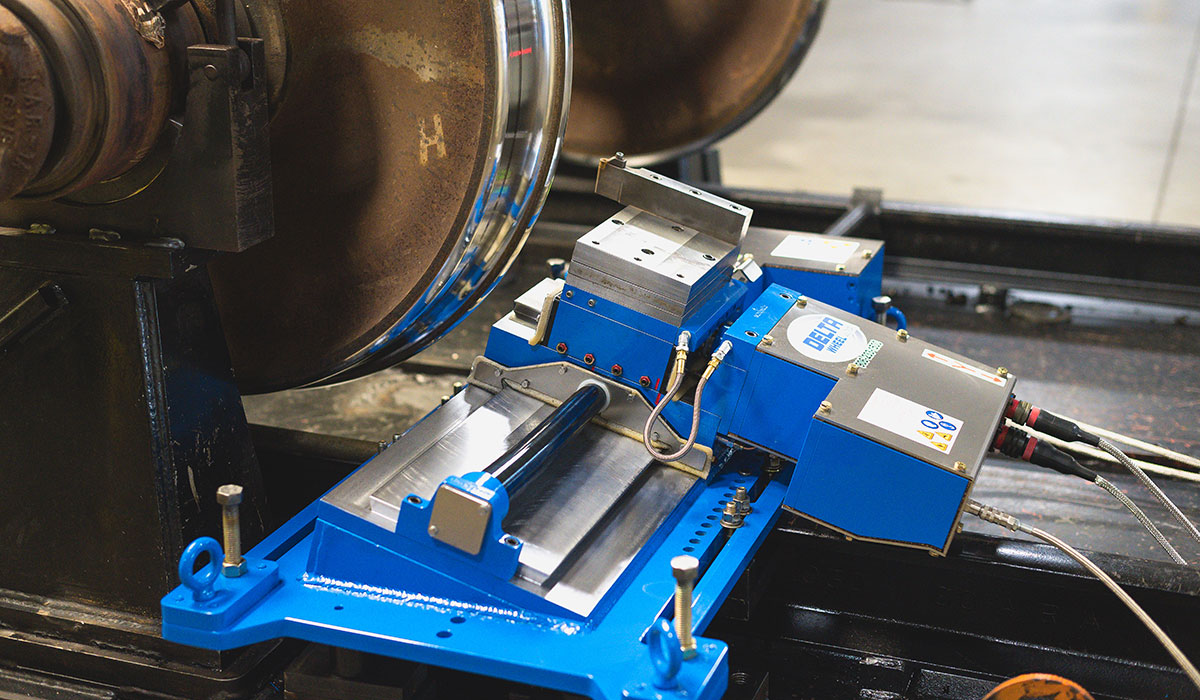

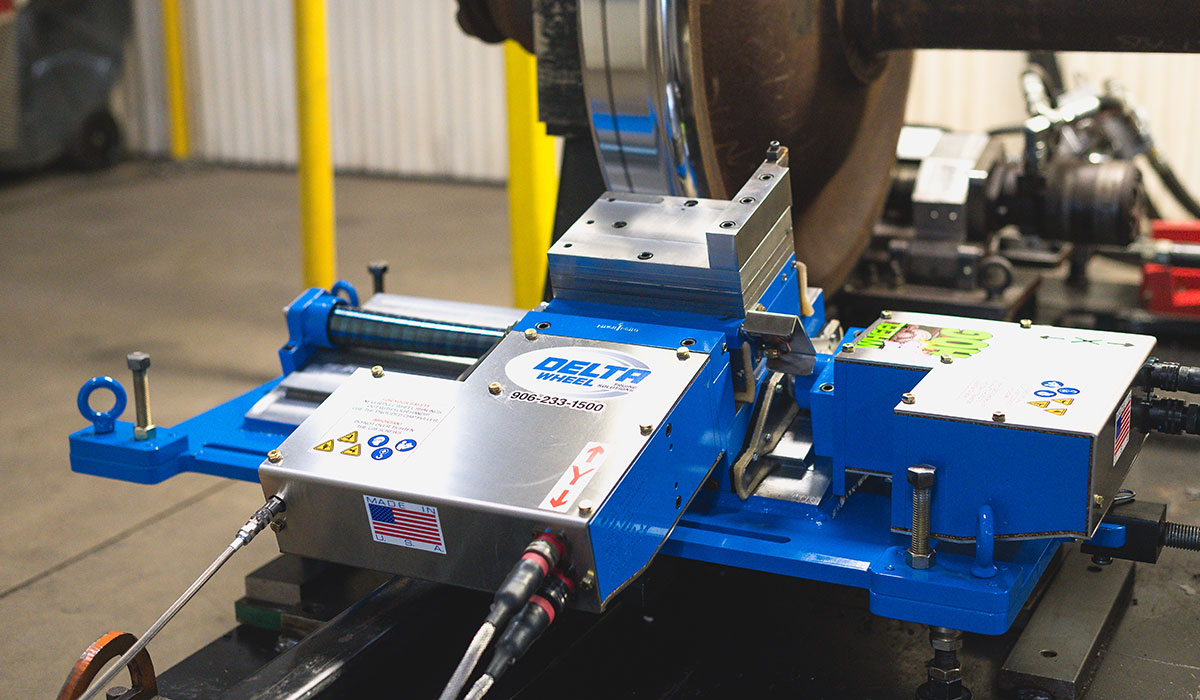

SAL1000

The SAL1000 is a fixture assembly with hydraulic powered drives for rotating non-powered wheel sets. Giving you the ability to re-profile non-powered wheel sets using the Wheel Hog as your cutting source and a hydraulic power unit and drive system as your drive source.